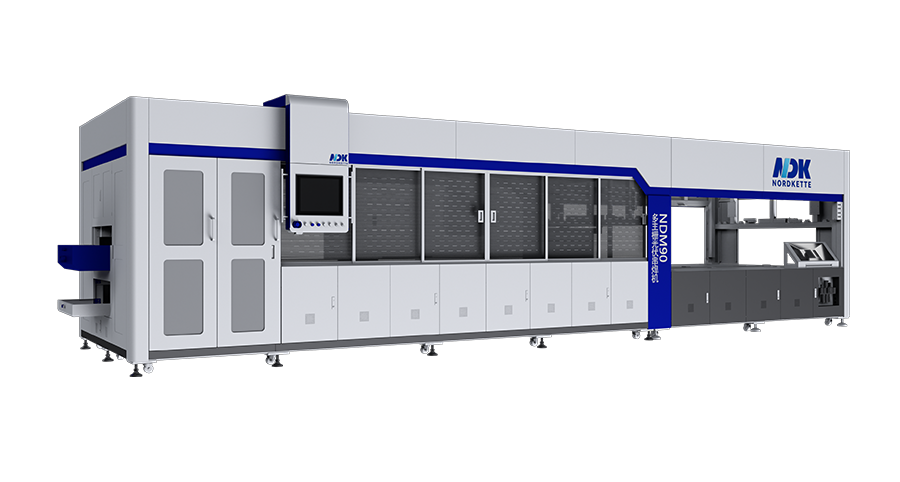

Relying on more than 10 years of experience in the field of 3C and industrial equipment manufacturing equipment system integration, the multi-main grid series welding machine for the photovoltaic module is introduced with AI visual recognition software, which can weld photovoltaic solar cells at high speed, with high precision, high production capacity, high compatibility, and battery string detection function. With a high degree of automation and low maintenance cost, the equipment is compatible with multiple processes, cells of various specifications, grid lines, and slice forms.

Equipment advantage

Equipment advantage

Strong product compatibility

- Different processes: polycrystalline, monocrystalline, PERC, TOPCON, HJT, etc.

- Different sizes: 156*156 ~ 230*230

- Different number of the grid: 9, 12, 15, 20....

- Different number of slices: full slice, half slice, three slices, six slicesShort slicing time

- With the compatible design of components, the slicing time is greatly shortened.

- Modular tooling is adopted, which is convenient for model change and maintenance.Many additional functions

-With the cell loading detection function

- With battery string online L detection function

- With battery string online appearance detection function

Automatic elimination of defective products

- Defective cells are directly eliminated during feeding to prevent defective cells from affecting the normal operation of the equipment.

- The defective battery strings are directly eliminated before unloading to prevent defective battery strings from flowing into the next process.

The high degree of intelligence

- Adopt AI visual recognition software to realize defect detection

- With the increase of detected defect samples, the detection results become more and more accurate.

- Customers can independently complete software learning and debugging of new defects caused by process changes.

Equipment characteristics

Equipment characteristics

Equipment characteristics Fast welding spee

- The highest production capacity can reach 8000~9000 pieces/hour (half piece), thereby greatly improving welding efficiency.

Feed with half-piece material box

- The cooperated use of various types of dicing machines can accelerate the whole machine's welding speed, and the equipment's cost performance is improved.

Self-developed software and algorithm system

- Master the core detection technology to facilitate customer customization and new demand introduction

- The modular design of each detection component can be selected and quickly docked according to customer needs

- Convenient MES docking system, open TCP/IP protocol and database