The rewinding machine equipment is a manual feeding I-shaped wheel, and the jacking device assists in lifting the I-shaped wheel. Automatic winding is started after pneumatic clamping. During high-speed winding, the tension control system of the follow-up oscillating bar can effectively suppress the wire breakage rate and increase production efficiency. The machine has high compatibility; the stroke of the clamping mechanism covers the size of the I-shaped wheel in the market, it is suitable for winding different specifications of products (commonly 33-44 microns), and it has a blade-cutting function module.

Equipment characteristics

Equipment characteristics

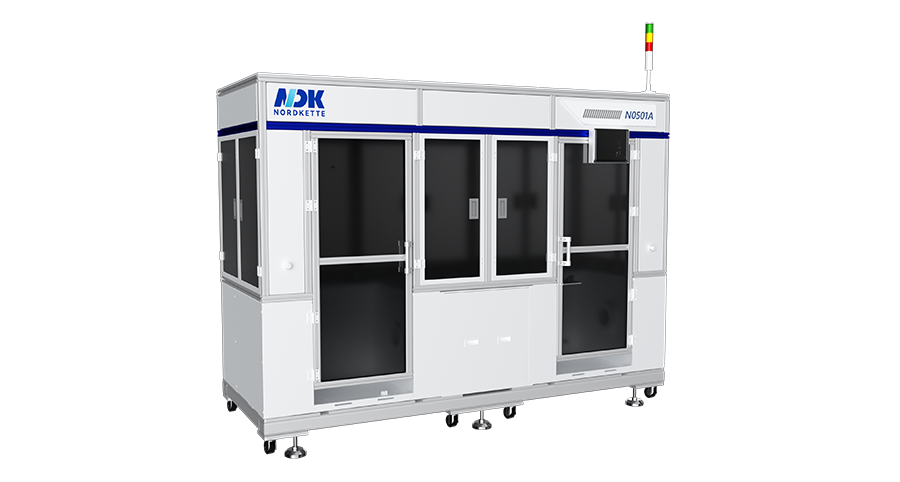

Overall size

- 3080(L)*1050(W)*2100(H)

Overall weight

- 3500KG

High accuracy of the winding arrangement

- Winding arrangement accuracy ≤±0.01MM

Fast winding speed

- Winding speed may reach 1200M/MIN MAX

Tension control system may suppress wire breaking rate

- Use the tension follow-up control system, the torque motor provides tension

- Effectively suppress the wire breaking rate during high-speed winding and improve production efficiency.Silk blade-cutting function

- The repeat positioning accuracy of the two-way module is ±0.01MM, and the servo motor drives two oil stone assemblies above three oil stone assemblies below, a total of 5 pieces.

High compatibility

- The stroke of the clamping mechanism covers the common size I-wheels in the market.

Angle detection, adjustment and correction

- The repeat positioning accuracy of the linear motor module is ±0.005MM, using a magnetic gauge.

- The angle detects the swing angle of the wire wheel, and the linear motor of the wire arrangement corrects the deviation according to the angle.